Fiber Bed (Candle Filters)

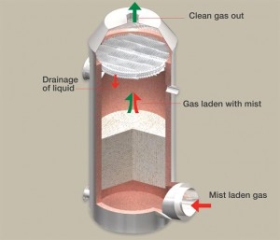

Fiber bed (candle filter) mist eliminators are used to remove fine particles from a gas stream. Fine particles include sub micron particles (i.e. below 1 micron) and particles between 1 and 3 microns. All fiber bed mist eliminators are cylindrical with fiber or fiber/metal mesh layer fitted between two concentric cages and are usually installed on a tube sheet in a tower. Soluble solids can be handled efficiently by dissolving them in a solvent. Insoluble solids can be handled to a moderate degree as well, however excess insoluble solids can cause plugging of the fiber bed mist eliminators.

Types of Galiakotwala Fiber Bed Mist Eliminators

Brownian Movement

Fiber Bed mist eliminators that are used for particles in the range of 0.1 to 3 microns.

Impaction Movement

Fiber Bed mist eliminators that are used for particles in the range of 0.1 to 3 microns.

For all types of candles cages and fiber are made from different materials based on customer applications.

Typical Applications

| Process | Location | Recommended Equipment |

|---|---|---|

| Sulphuric Acid | Drying Tower | IMW / IMW-CK / IMB / SX-CK Mesh Pad |

| Interpass Absorption Tower | BMW / BMB / IMW-AP | |

| Final Absorption Tower | BMB / BMW / IMB / IMW-AP / SX-CK Mesh Pad | |

| Cross Flow / Product Stripper | BMB / BMW | |

| Acid Concentrator | BMB / BMW | |

| Oleum Vent Tanks | BMB / BMW | |

| Tail Gas Scrubber (Caustic / Ammonia) | BMB / BMW | |

| - Chlorine | Wet Chlorine | BMB / BMW |

| Dry Chlorine | BMB / BMW | |

| Hydrogen | BMB | |

| Phosphoric Acid | Absorber | BMB / BMW |

| Nitric Acid | Evaporator Towers | BMB / BMW |

| Urea Fertilizer | Prilling Towers | BMB / BMW |

| Nitric Acid | Catalyst | BMB / BMW |

| Post Absorbing Tower | IMW-AP / IMB | |

| Neutralizer and Evaporator | CK Mesh Pad / BMB / BMW | |

| Blue Haze Applications | Plasticizer Solvent Fume Removal | BMB / BMW |

| Lube Oil Haze from Rotating Equipment | BMB / BMW | |

| Metal Working Operations | BMB / BMW | |

| Plastics Processing | BMB / BMW | |

| Asphalt Production | BMB / BMW | |

| Loading Fabric, Testing and Coating | BMB / BMW |