Alloy Acid Piping

In the past decade, acid piping has advanced to metallic alloys as the material of choice. This is due to the inherent advantages of alloy acid piping over conventional materials.

| Cast Iron Piping | Alloy Piping |

|---|---|

| High corrosion rate (upto 2.5mm/yr) | Low corrosion rate (less than 0.025mm/yr) |

| Large number of flanges therefore higher risk of acid leaks | Welded construction reduce number of flanges minimizing risk of acid leaks |

| Iron sulphate formation (greenish sludge) causing plugging of mist eliminators and packing | No iron sulphate formation due to negligible corrosion resulting in reduced plugging/maintenance of tower internals |

| Constant requirement of maintenance and inventory of spares in case of acid leaks. No possibility of welding | Pratically zero maintenance and no requirement for any spares. Full possibility to weld and repair on-site using conventional welding techniques |

| Difficult handling due to heavy weight and bulky | Easy erection and flexibility due to light weight and compact size |

| Low ductility, higher risk of brittle failure resulting in lower safety levels | Higher ductility, minimized risk of brittle failure resulting in higher safety levels |

| Designed and operated at lower velocities due to risk of erosion and corrosion | Designed and operated at higher velocities without risk of erosion and corrosion |

The life cycle cost of Galiakotwala Alloy piping will be lower due to significant reduction in maintenance. Once installed alloy acid piping will usually last the full life of the plant with minimal maintenance. Alloy acid piping has proven itself with many installations worldwide, more than 40,000m of alloy acid piping has been installed all over the world.

Alloy Nozzles, Sleeves And Dip Pipes

Areas in the Acid plant that are most susceptible to corrosion and leakage, and requiring constant maintenance can be converted to Alloy material thereby reducing or eliminating maintenance. Galiakotwala manufactures nozzle, sleeves, dip pipes and other equipment manufactured from alloy materials that reduce or eliminate corrosion and have a long life.

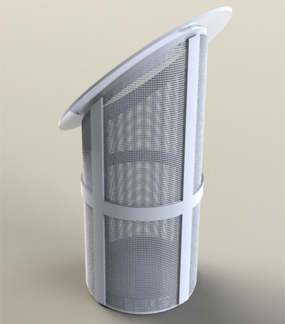

Alloy Strainers

Galiakotwala can supply both inline strainers as well as strainers for side and bottom outlet nozzles. These can be made from both mesh and perforated plate. Alloy strainers last much longer with design that minimizes plugging and is easy to clean. Vortex breakers can be combined with strainers and nozzles, and supplied as one equipment.